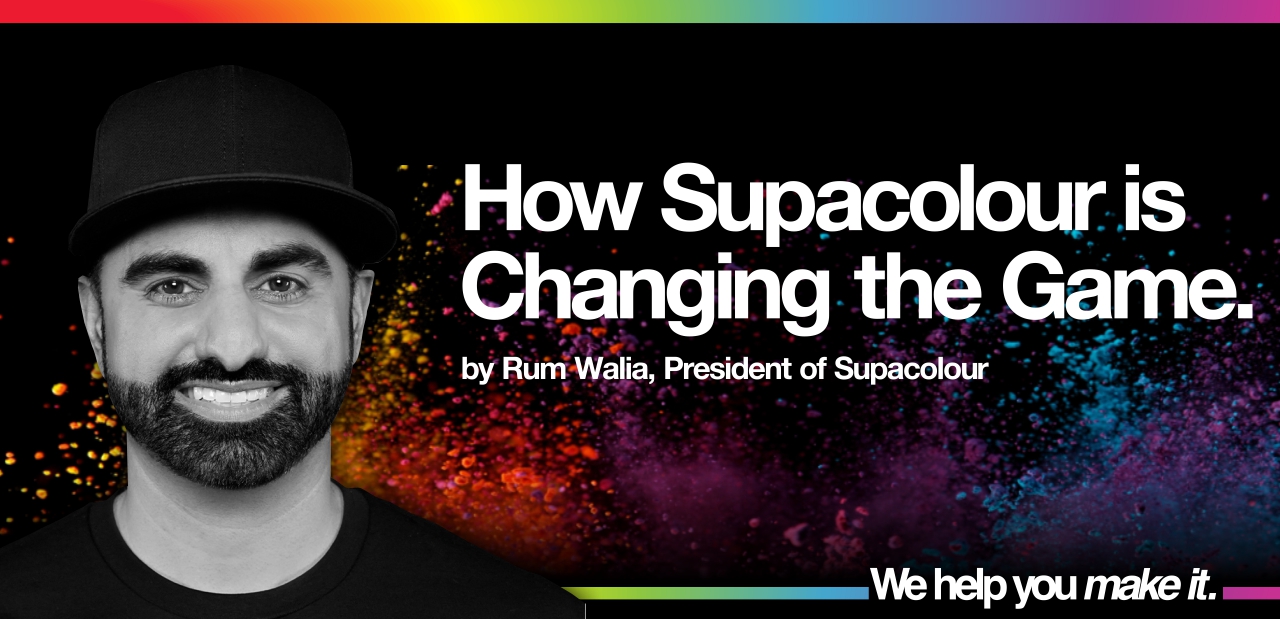

by Rum Walia, President of Supacolor

The story of Supacolor goes far beyond our heat transfers. As we like to say around here, “We’re more than just a heat transfer company.” Our company’s ethos is manifested in our belief that anything is possible and in our aspirations to help others make it. In one sense, by ‘make it’, we help in the making of t-shirts, caps and bags – but what we are really saying is that we help people make it in business and in life. We are forever linked to our Supafam (our beloved customers) because we only exist because of them. When they win, we win. Our success is predicated on how we help people grow, not by how much Supacolor we sell. A heat transfer isn’t much of anything unless it is applied to a garment. In the same way, Supacolor isn’t much of anything without its Supafam community. We’re incredibly grateful to everyone that helped us grow and we are committed to helping those around us do the same.

Supacolor was created by decorators for decorators. The founding partners of Supacolor, Bill Armitt, Mike Modgill and myself, all have experience running our own garment decorating businesses – screen printing is in our DNA. We understand the risks and challenges decorators face every day.

And more specifically, we know the challenges of printing multi-colored designs with gradients on complex fabrics, whether using inks or threads. For example, the combo of a 6-color design and a 10-piece job would make most decorators run for the hills. Running these jobs didn’t make any sense. While everyone else saw a barrier, we saw an opportunity and jumped all over it.

Supacolor was created to solve problems for screen printers and embroidery shops. Allowing them to say yes, when before the answer was no. With Supacolor and a heat press, you could now print anywhere. You no longer needed expensive equipment, a lot of space, or skilled, experienced printers. Creating freedom and opportunity for decorators to grow their business in ways that complemented what they were already doing.

The ambition to solve the problem of printing multi-colored designs was the motivation for inventing Supacolor. Bill and Mike talked about this frequently back then – they didn’t want to stop the carousel presses to screen print complex jobs, but they also didn’t want to turn away customers. They just knew there had to be a better way.

So, they set out on a journey that would see them innovate, collaborate and ultimately bring people all over the world together.

The early days were challenging. Bill and Mike had to find a digital offset press. Getting access to something like this wasn’t easy, especially when it was very experimental. Sticking PET Film through a press could damage it. But they found a used one for sale and made a big bet on the future. With the digital front end in-hand, the guys had to find a way to screen print the rest of the transfer.

Believe it or not, Bill was screen printing the back of the transfers on a hand bench trying to get the registration on point. The limitations and the inaccessibility to equipment didn’t stop them, because the hustler never quits. The one thing that our entire Supateam has always had in common is that we are obsessed problem-solvers. Relentless in the quest to find something better, Supacolor was born.

You’ve probably heard us say Supacolor is the “World’s Best Heat Transfer.” You might think that we’re being arrogant by saying this, but we really believe it. Let me tell you why. Its beauty lies in the simplicity of its construction and the versatility of its performance.

To start, the construction and design of the transfer is elegant. Every Supacolor is created with a combination of digital printing and screen printing techniques, making it a true hybrid transfer.

On the front end, we use the very best digital offset press technology to print every color except white. These half-million-dollar presses are set up with seven colors (cyan, magenta, yellow, black, violet, orange and silver), giving us a broad spectrum of colors that are unmatched in the industry.

Our printing capabilities include Pantone color matching (think T-mobile pink or Coca-Cola red), printing CMYK and specialty matte metallics. We can print graphics super sharp. I’m talking about line weights as small as 1 pt (0.35 mm), so you can print small details. Every. Tiny. One.

We finish each heat transfer off with one of three different kinds of adhesives to print on various fabrics. What’s different about Supaoclor is that we’ve created unique transfers specifically suited for different materials. Why? Because we want our transfers to last longer than the products they are applied to. It doesn’t matter if it’s t-shirts, sweaters, caps or bags. Supacolor’s formula is designed to make the transfer look good for as long as possible. That’s why they’re wash tested by a third party lab and proven to last more than 70 washes. We want your designs to look amazing, even when the garment is wearing out. If you don’t look good, we don’t look good.

The real magic of making Supacolor actually starts before we even get to the processes I’ve just described. It begins on the front end with our prepress team: Supaflow. This is where our team prepares the submitted artwork. Anyone that has been in the print industry for even a short while knows that you’re only as good as the artwork you get.

Our team goes to great lengths to ensure that every graphic submitted to us is treated with the utmost care and given the attention it needs to print optimally. This means that if we need to redraw your artwork, we will. At no extra charge. It’s our way of making sure every Supacolor is made to the highest standard.

When you add up the sum of the parts – digital printing, screen printing and Supaflow – you can see why we end up with the World’s Best Heat Transfer. A transfer that we proudly serve up daily, to thousands of customers every month. Each step of the way, we inspect and assure our quality. When we don’t get it right, we don’t blame our customers. We take ownership and make it right, because we’re guided by our daily mantra: Supafast. Supaeasy. Supacolor.

This is more than a marketing line. It’s who we are.

We are Supafast: We understand that a quick turnaround time is critical in this industry.

We are Supaeasy: Nothing is too much trouble. We make it easy for everyone involved.

We are Supacolor: We take pride in everything we do. We don’t settle for good; we aim for great.

I’ve said it before: we are more than just a heat transfer company. We are Supacolor. Everything we do is about the people. It always has been, and always will be. What we do and how we do it isn’t as important as why we do it.

Why do we do it? To help you make it, in business and in life. So let me ask you: how can we help you make it?